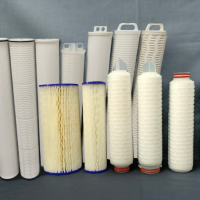

Material and Construction

●pleated filter layer which could not only increase the amount of pollutants and flow,but also increase service life.All parts of the seal are made of non-adhesive hot melt welding technology,and the melt seal constitutes a complete whole.

Application

1.Electronics industry:high purity water pre-filtering etc.

2.Food and beverage industry:mineral water,alcohol,juice filtration.

3.Medical and health industry:filtration of liquids,gases,etc.

4.Chemical Industry:organic solvent filtration.

5.Oil industry:oilfield water filtration.

Main Features

The pleated filter cartridge is made of ultra-fine polypropylene fiber membrane and non-woven fabric or (wire mesh) as the support layer. The shell, center rod and end cover of the filter cartridge are processed by hot-melt welding technology, without any adhesive, leakage, medium shedding and secondary pollution. Microporous PP pleated filter cartridge is widely used in filtration industry as front-end pre-treatment and terminal filtration unit. In the chemical, pharmaceutical, energy, environmental protection and other industries of a variety of media filtration and water treatment process, are essential operation unit.

1. Excellent chemical compatibility, suitable for filtering strong acids, bases and organic solvents

2. The filter membrane is pleated deep filtration with large filtration area

3. Low pressure difference, strong pollution capacity and long service life

4. There are many kinds of filtering precision to choose from

5. Progressive pore size change provides ultra-high pollutant carrying capacity